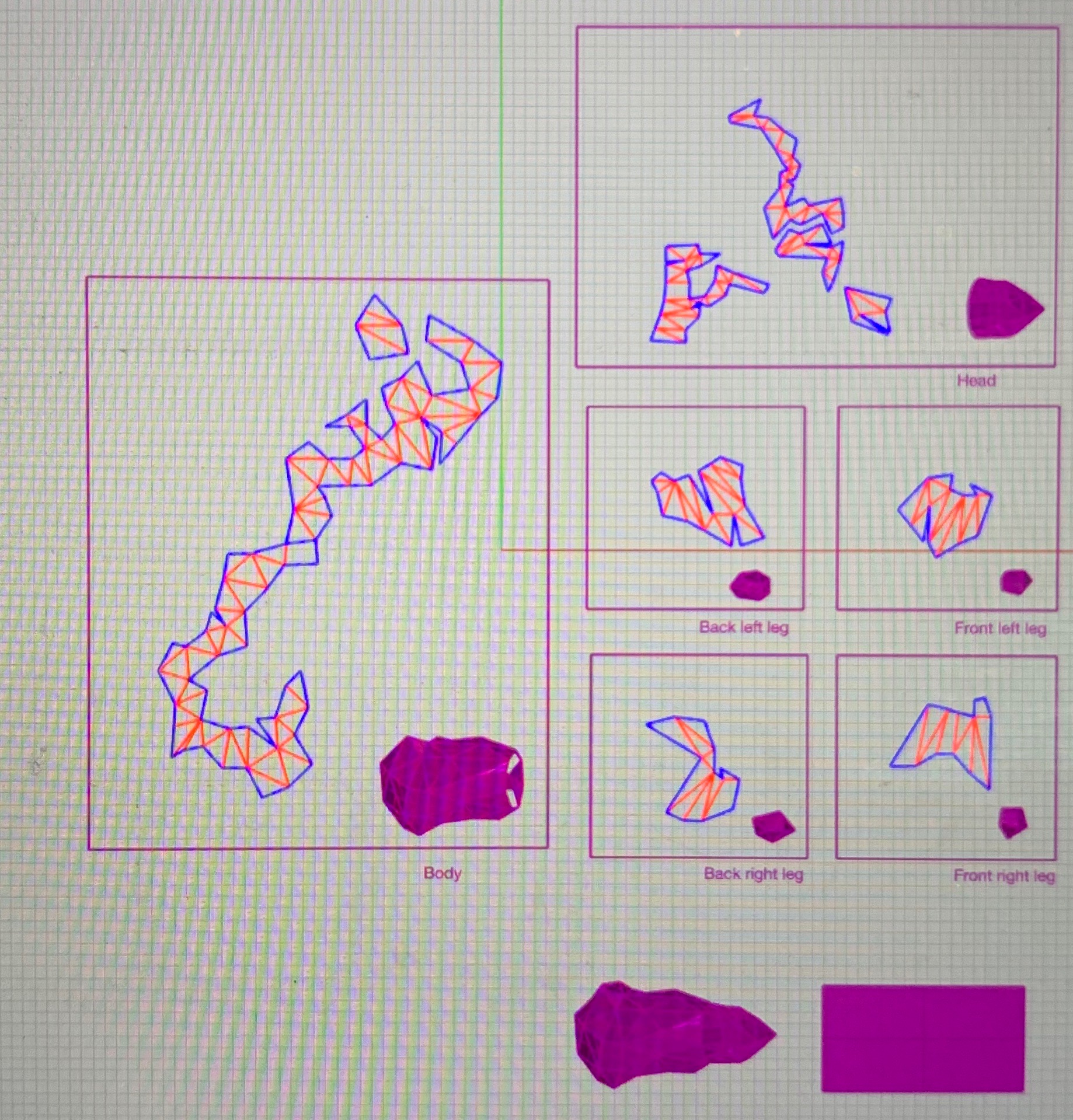

This black bear was digitally modeled in Rhinoceros6 as a Non-Uniform Rational Basis Spline (NURBS) object, a smooth object created using mathematically accurate representations of curves. The object was then converted into a triangular mesh object, unrolled, and modified before it was laser cut out of cardboard and assembled.

In Progress:

The piece was created in a class called Digital Fabrication (ARTS 4017) in Spring 2020. Throughout the semester, I used laser cutters, 2-axis CNCs, and other fabrication tools to create art pieces that were modeled using computer-aided design.

Description

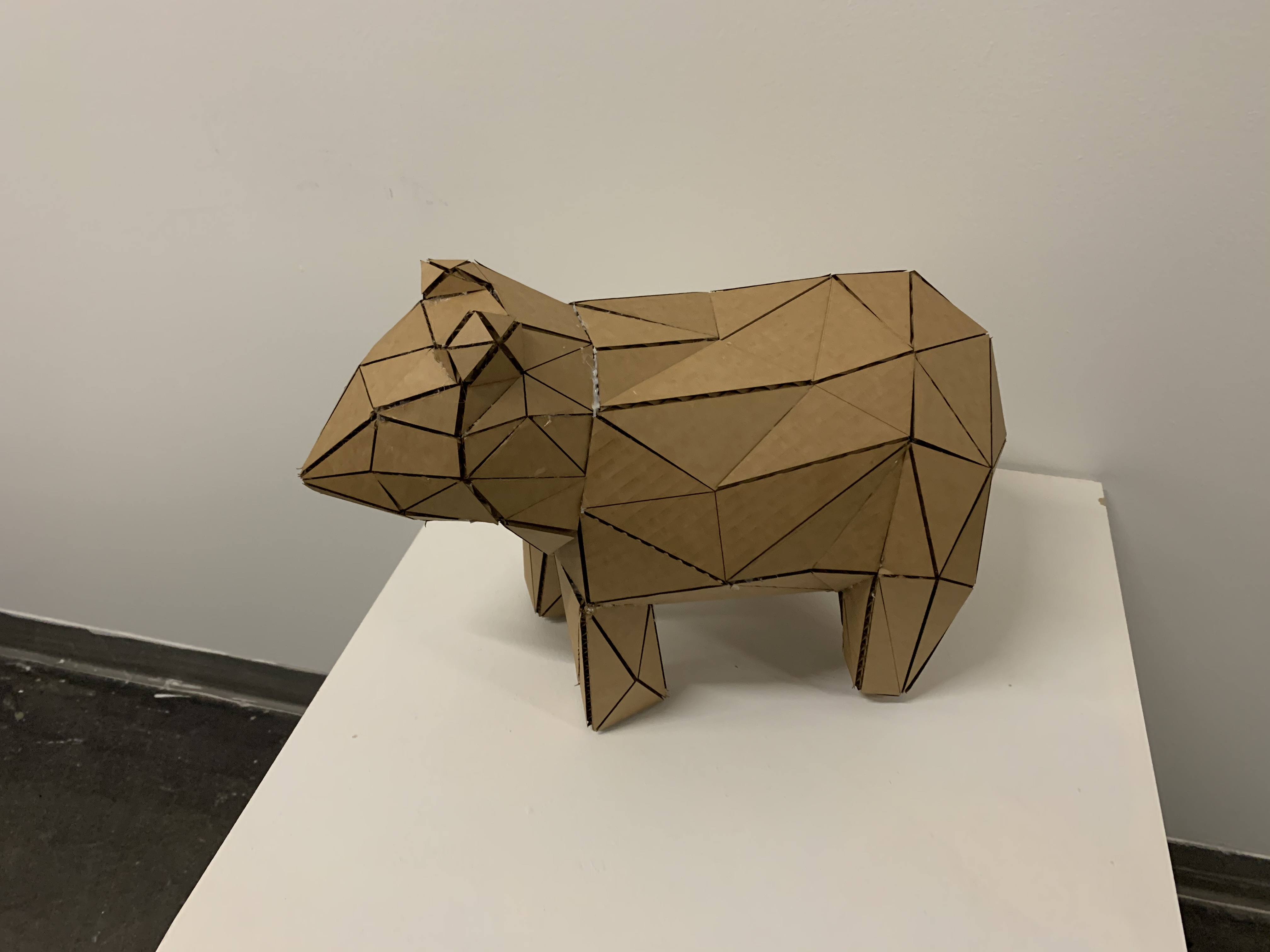

My favorite animals to see in the wild are black bears. I wanted this piece to have the same powerful and sturdy presence, so I thought cardboard would be the perfect medium to accomplish this. I also wanted to do something a little bit more technical unfolding-wise, because I love doing modular origami.

I didn’t really like how the head fit onto the neck, but it does add a little bit of movement to the bear’s head and it is a natural breaking point on the bear’s body. If I were to do this again, I might try and make the model in rhino fit the head a little bit better. Originally, when I was modeling, the head didn’t show enough detail when I unrolled it at the same level of detail as the body. Ultimately, I really enjoyed doing this project and thought it turned out really well. One day, I would love to make this bear life-sized! The final piece was 11.85” tall x 17.37” long x 9.17” wide.

Final:

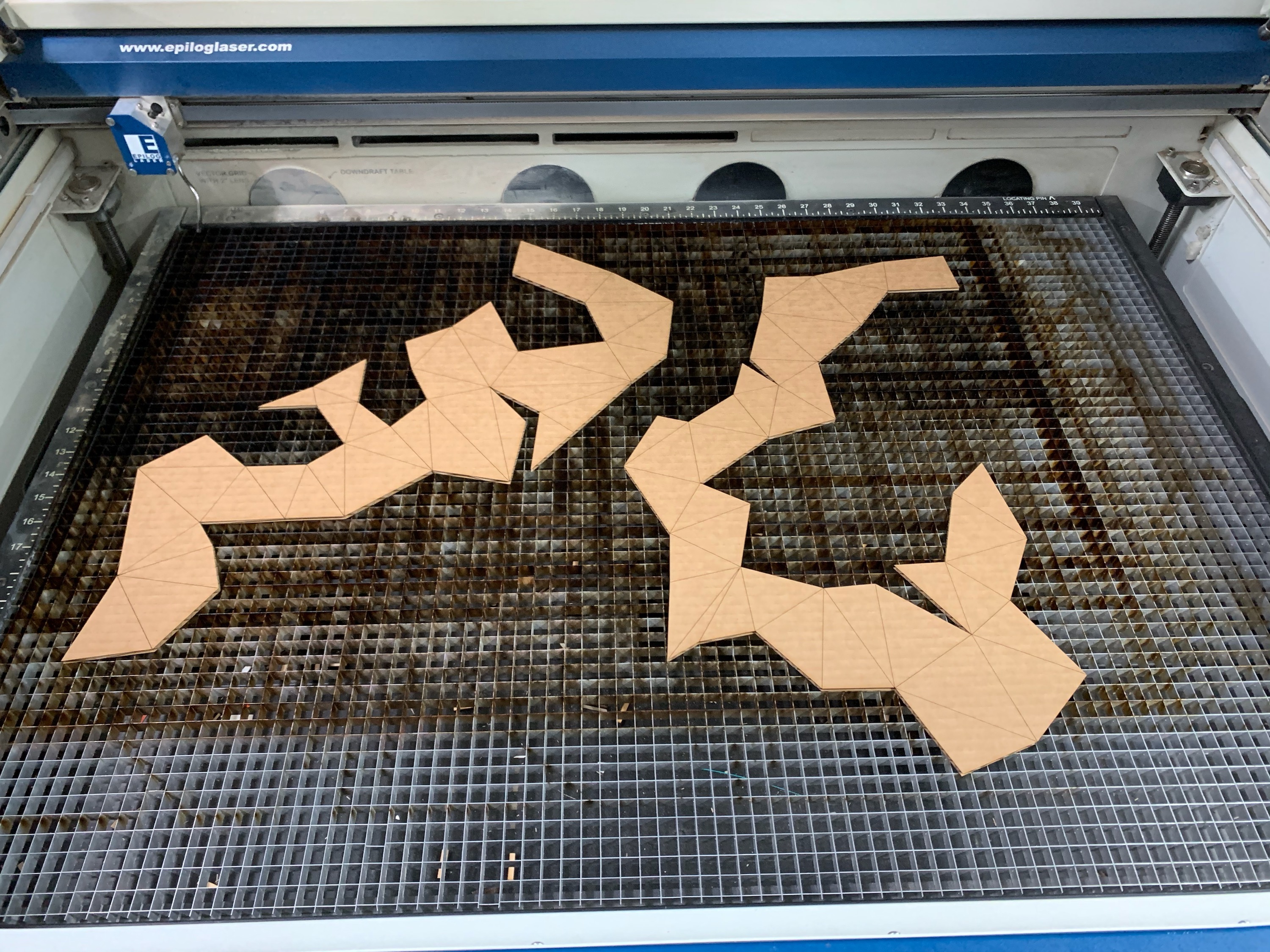

Laser Cutter Settings:

To cut through the 1/8” thick cardboard, the vector settings for the Epilog Laser Cutter were 50% speed, 100% power, and a frequency of 50. To engrave the 1/8” thick cardboard, the vector settings were 100% speed, 50% power, and a frequency of 50. These settings were determined using trial and error.